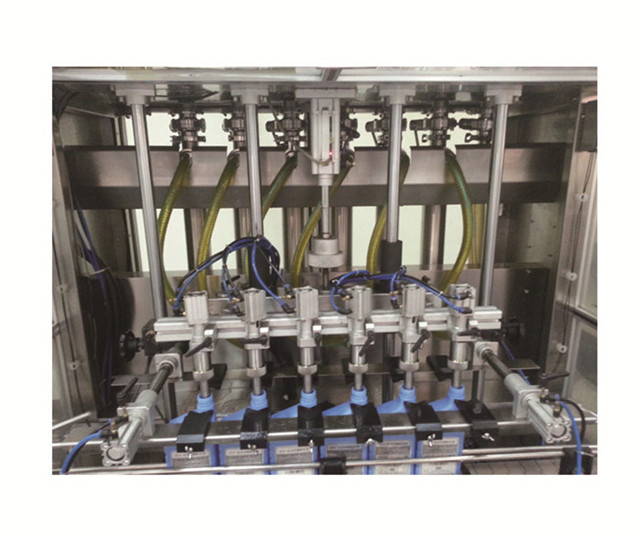

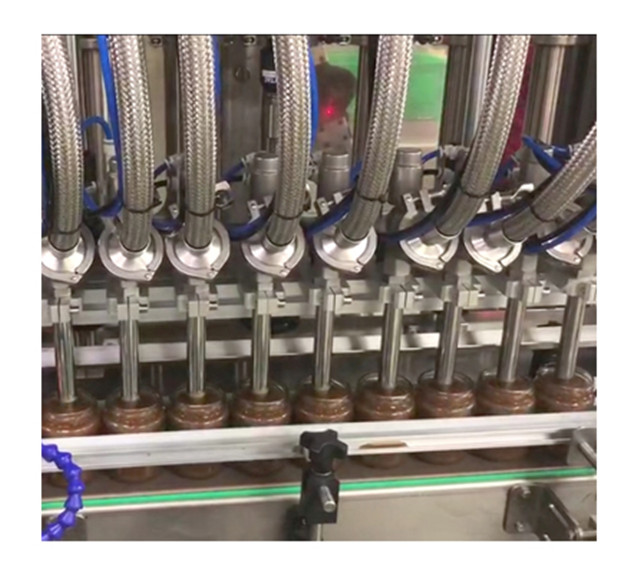

Automatic Linear Piston filler is an extremely flexible filler capable of filling accurately and rapidly any viscous liquids. Product delivery from your bulk tank to the pistons can be configured with a buffer tank utilizing a level-sensing float, a manifold with direct draw, or re-circulation methods. The Automatic Linear Piston Filler is manufactured with a 304 stainless steel frame and is capable of supporting 1 to 12 fill heads. PLC controls, touch screen HMI, food grade contact parts, stainless steel and anodized aluminum construction and many more features come standard. Automatic Piston Fillers are designed to add efficiency to any production line used in the cosmetic, food service, specialty chemical, pharmaceutical, and personal care industries. Additional options are available for sanitary, hazardous, flammable and corrosive environments.

Piston Bottle Filling Machine are ideal for filling lotions, creams, gels, conditioners, honey and sauce.

VKPAK automatic linear servo-motor liquid piston fillers are suitable for a wide variety of products from water-thin to thick but flowable products.

With high running speed.

Multiple filling nozzles as 8, 10, 12, 14 or 20.

Brief Introduction:

The serials are Piston Bottle Filling Machine that has the capability of filling liquid with viscous and thin viscosity. VKPAK Piston Bottle Filling Machine are ideal for filling lotions, creams, gels, conditioners, honey and sauce.

VKPAK is a well-known brand in the filler machine industry. We have rich experience and expertise to develop full line of industrial filling machines. If you have specific demands, please feel free to contact us at anytime.

Features:

- Application - sauce, shampoo, body wash, emulsion.

- Filling range from 50ml to 5000ml.

- Four (4) to twenty four (24) filling nozzles

- PLC controlled with touch screen panel, easy access to all settings.

- Volumetric filling system by piston pumps, driven by servo motors.

- Drip tray protects bottles from nozzle product dripping.

- 50 products can be stored in memory for recall.

- Liquid contact parts in stainless steel SUS 304.

- Bottle width (diameter): 50mm-90mm

- Bottle height: 120mm-300mm

- Capacity: ~ 120 BPM.

Main Parameter:

| Nozzle Number | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-1000ml/ 250-2500ml/500-5000ml | |||

| Production capacity | Bottle/h | 1000-3000 pcs/Hour ( Depends on Filling volume) | |||

| Quantitative error | % | ≤±1% | |||

| Voltage | V | 380V/220V, 50Hz/60Hz | |||

| Power | KW | 2.5 | 2.5 | 2.5 | 2.5 |

| Air Pressure | MPA | 0.6-0.8 | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |