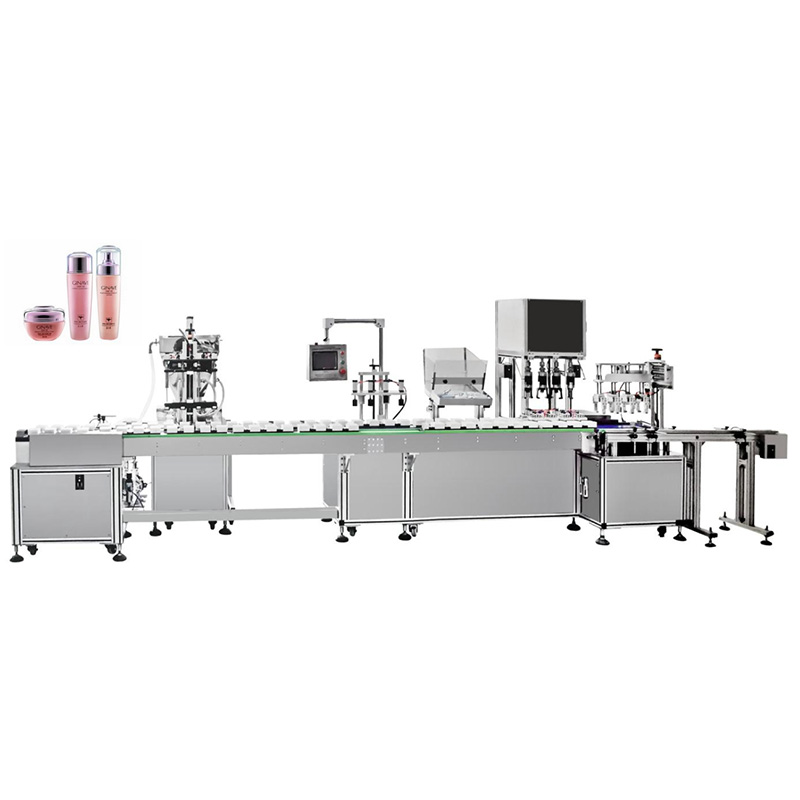

This production consists of bottle feeding table, peristaltic pump filling, feeding sprayer pump(glass dropper),pre-capping,servo capping, labelling and bottle collection table.

Brief Introduction:

This sprayer pump, glass dropper bottle filling and capping machine includes the turn table feeding bottle, automatic filling, automatic feeding sprayer pumps (glass dropper), capping, labelling and bottle collection table.

This production consists of bottle feeding table, peristaltic pump filling, feeding sprayer pump(glass dropper),pre-capping, servo capping, labelling and bottle collection table.

This production line consist of Turn table as bottle sorting and feeding system , filler and capper station, labeler , mainly used in small doses of solution 1- 4Oz, can be used single independently. meet the GMP requirements.

1. It is with reasonable structure, higher precision in filling, reaching the advanced level in domestic same business. Meet with requirement of GMP standard completely.

2. Automatic Bottle turntable is a newly designed machine, it can arrange disorderly and unsystematic bottle and send them to orbits.

3.E-cigarette filling capping machine is a third generation product, humanmachine interface operation, filling by peristaltic pump, replace air cylinder with vacuum drive manipulator for plugging, high stability

and percent of pass. Constant torque cap screwing.

4. No bottle no filling, no plug no capping and automatically stop if cap and plug is under-supply.

This monoblock amber/ boston glass dropper bottle filler capper machine is design for the plastic or glass pipette bottles. It is widely used in eliqudis/ejuice ,Pharma, CBD oil, nurture Diagnostic, Healthcare industrials, suit for fill eliquid, tincture, serum, sweet oil, cannabis oil, hemp oil and MTC oil, Vitamin liquids, essential oil etc.

Features:

- Liquid, lotion, cream generic.

- Automatic filling, within corking, capping, the container is discharged.

- Linear operation, automatic maneuver recycled jig.

- Fixture adjustable, exchange bottle type simply adjust the clamp to fill different bottle.

- Servo motor control sneak follow filling, to prevent the filling material outside the spray when the bubble.

- Servo motors combined with the rotary valve, piston quantitative filling, easy to control, regulate simple, high precision filling volume for the filling material more widely.

- Capping servo lifting, robot gripping capping, cap size adjustable, capping torque adjustable, no damage to the cap, capping a high success rate.

- Robot automatically discharged finished, convenient and reliable.

- Equipped with moving wheels, easy to move. Machine with sanitary stainless steel, aluminum manufacturing quality, clean and hygienic.

- Anyone can skillfully operate in a short time.

- Man-machine interface with a recipe function, simply replace the product that you need to select the recipe can be realized easily and quickly.

- The most suitable for the daily output of 15,000 to 25,000.

Main Parameter:

| Filling volume | Ml | 5-100 |

| Production capacity | Bottle/h | 1500-3000 |

| Quantitative error | % | ≤±1% |

| Cap feeding rate | % | ≥99% |

| Capping rate | % | ≥99% |

| Source voltage | V | Three-phase four-wire system AC220V 380V ±10% |

| Consumed power | KW | 2 |

| Gas supply pressure | MPA | 0.4-0.6 |

| Air consumption | M3/min | 0.2 |