This Automatic Piston Type Sauce Filling Machine is piston type filling machine special made for filling cream or liquid foodstuff such as ketchup, sauce, honey, jam, peanut butter , mayonnaise, salad dressing etc.

Automatic piston filling machine is also named high viscosity liquid automatic piston filler. The filling machine is controlled by a servo system, so it has better accuracy and is easier to adjust.

The piston filler machine is widely used in the filling of high viscosity liquid and paste products. Such as: honey, lotion, tomato sauce, rice wine, seafood sauce, grease, lubricants, detergent, washing liquid and other high viscosity liquid.

Brief Introduction:

This Automatic Piston Type Sauce Filling Machine is piston type filling machine special made for filling cream or liquid foodstuff such as ketchup, sauce, honey, jam, peanut butter , mayonnaise, salad dressing etc.

Foodstuff standard product contact parts , and ok for high product temperature.

CIP product hopper , easy for cleaning.

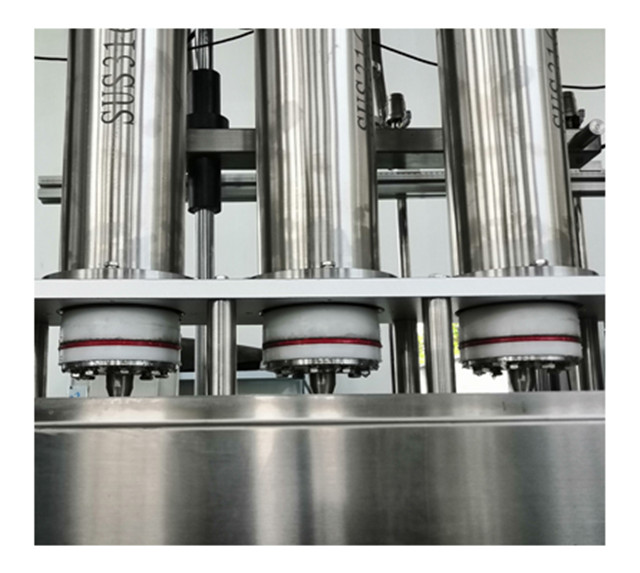

Filling head quantity can be custom-made according to different production capacity such as 6/8/10/12/16 /20 heads.

The filling system is driven by servo motor which assure high filling accuracy ,also easy to set filling volume on the touch screen directly.

Features:

- Made by high quality 304 Stainless steel, it is durable.

- 316 stainless steel product contact parts is available for optional according to product features.

- Dosing system is driven by servo motor, it assure high filling accuracy.

- Liquid receive tray is available in case any dripping from filling nozzle.

- Air blow off filling nozzle is available for sticky product to avoid tail stringing on nozzle

- CIP Product hopper

- No bottle no fill.

- Linear structure which is flexible for varies bottle size.

- Controlled by PLC and operation through touch screen.

- No tooling needed to change over different size bottles.

- Quick-install connecting parts , it is easy to disassemble and clear machine.

Main Parameter:

| Model | Unit | STRFS | |||

| Nozzle Number | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-1000ml/ 250-2500ml/500-5000ml | |||

| Production capacity | Bottle/h | 1000-3000 pcs/Hour ( Depends on Filling volume) | |||

| Quantitative error | % | ≤±1% | |||

| Voltage | V | 380V/220V, 50Hz/60Hz | |||

| Power | KW | 2.5 | 2.5 | 2.5 | 2.5 |

| Air Pressure | MPA | 0.6-0.8 | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |