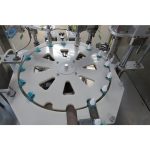

Integrated the filling and stoppering machine in one compact machine, it can finish the following procedure automatically , filling , stopper arranging, stopper putting, and stopper pressing, bottle out feeding, etc. the machine running smoothly, and stable function, accurate filling, and comply with GMP.

Oral Liquid Syrup Filling and Capping Machine has the functions such as Oral Liquid Syrup Filling and Capping Machine has the functions such as automatical screw type bottle feeding, bottle detecting (no bottle no filling, no bottle no cap feeding ), filling, cap feeding and capping automatically.

The singe (double) head automatic ointment filling machine adopts programmable logic controller (PLC) human and machine interface technology, equipped with imported photoelectric track switch from Korea, which is suitable for filling ointment products in the industries such as ointment, oil products, syrup, shampoo, bechamel and fruit juice etc. The filling nozzle will be automatically inserted into the bottle to carry out the filling and then rapidly ascend, which can reduce the air bubbles. The product integrates electric and pneumatic functions into one, with reasonable design, stable performance, accurate quantity, glass table surface, automatic bottle feeding, steady operation without noise, electric speed control to the filling speed and filling volume and convenient maintenance and cleaning. The new type filling equipment is the best choice for the realization of automatic production.

Main Parameter:

| Filling volume | Ml | 5-250 |

| Production capacity | Bottle/h | 1000-3000 |

| Quantitative error | % | ≤±1% |

| Cap feeding rate | % | ≥99% |

| Capping rate | % | ≥99% |

| Source voltage | V | Three-phase four-wire system AC220V 380V ±10% |

| Consumed power | KW | 1 |

| Gas supply pressure | MPA | 0.4-0.6 |

| Air consumption | M3/min | 0.2 |

VKPAK Monoblock liquid bottle filling and capping machine incorporates two packaging operations in a single stage and is therefore more economical, versatile and suitable for busy production centers. They have high production output that ranges between 30 -100 bottles per minute depends on the type of model selection and can fill containers ranging from 30-1000ml.The operation of the liquid bottle filling and capping machines starts with unscrambling of the bottles in a round turn table before they are feed to a conveyor for filling. The filling stage has nozzles with self centering devices that are plunged to container and achieve very accurate fill. Foam free filling is achieved using nozzles that rise up during the operation. Our equipments follow the international standards and have CE certification.The equipment is assembled from high quality materials such as SS 316 for all contact parts and SS 304 for other parts. The bottle liquid filling & capping machine uses modern control technologies that implement “no bottle–no filling” and “no caps–no capping system”. In addition, the motor has variable speed control and all parts are driven by a single motor. After filling, the bottle passes to the capping section where they are sealed. Special flow meters are used to record the fluid flow while other sensors record the number of bottles.

1. A desired capacity can be quickly and precisely acquired since a singleaxis adjusting piston is adopted in this machine.

2. Parts of the piston is contacting the liquid is made of stainless steel trated with hard chrome to enforce the surface hardness.

3. Bottle delivery line, positioning of the bottle and capping operation are motivated by air cylinder.

4.Automatic cap sedling is designed for those bottle mouths to be sealed wiht aluminum cap and/or spiral-type cap.

5. It is also possible for sealing with plastic cap and the sealing requirements can be adjusted according to the materials of the cap.

6. A safety equipment is attached to this machine, which will automatically stop its operation in case of any fell down of bottle,improper positioning of the bottel to be capped, or of the manual hand wheel is intruded.

7. The soft device permits to reduce the friction loss of machines.thus to prolong the service life of this machine. When specification of the cap is changed, only to replace the star wheel required, the height can be also adjusted according to that of the bottles to be capped.

8. It is very easy to wash and clean.

9. A stepless speed varlation motor is used, the operation speed can be adjusted as desired.

10. It operates independently, or it can be connected with the automatic labelling machine for a consisted intergrated automatic production.

11. Liquid Automatic filling Cap Machine is driver by piston motion.

12. All process of the delivery of bottle, positioning of the bottle, filling tube, and sealing are automatiically operated and meet with the G.M.P. requirements.