Eyedrop filling and capping machine is the new machine which in these years we design and make it. Man can set he nuber of steps peristaltic pumps with microcomputer to perform metering filling (special occasions with ceramic pump).

Brief introduction:

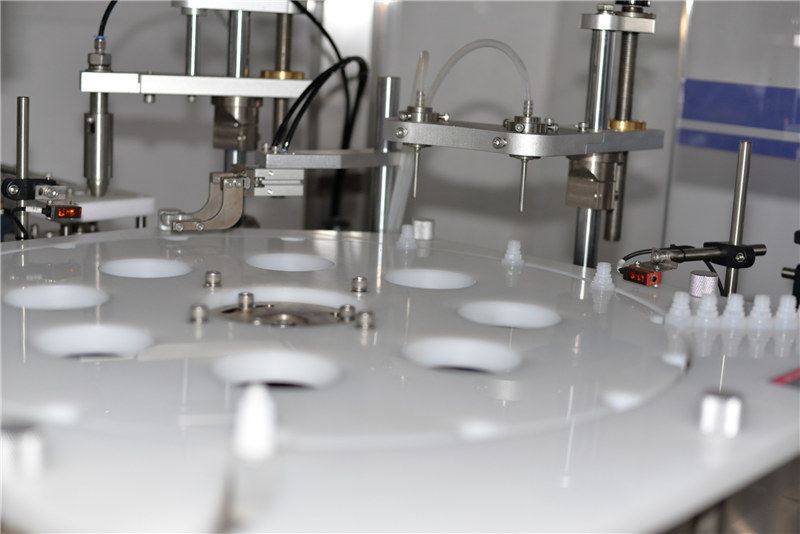

This machine is the new machine which in these years we design and make it. Man can set he nuber of steps peristaltic pumps with microcomputer to perform metering filling (special occasions with ceramic pump). It has the functions: automatic filling, automatic plugging and capping. The machine is equipped with special internally unique mechanical hand. These can ensure the plug and the out cover to enter the bottle, so that it achieves fully automatical. The machine fully meets with new GMP requirements.

Main technical parameters:

Filling Volume 2-20ml

Productivity 40-60 80-120 Bottle/minute

Filling Precision ≤±1%

Power Supply 220V/50Hz

Capping Rate ≥99%

Stoppering rate ≥99%

Air Supply 2 m3/h 0.4-0.8Mpa

Power 1.0 kw

Weight 400 kg

Dimension 2400*1100*1500mm

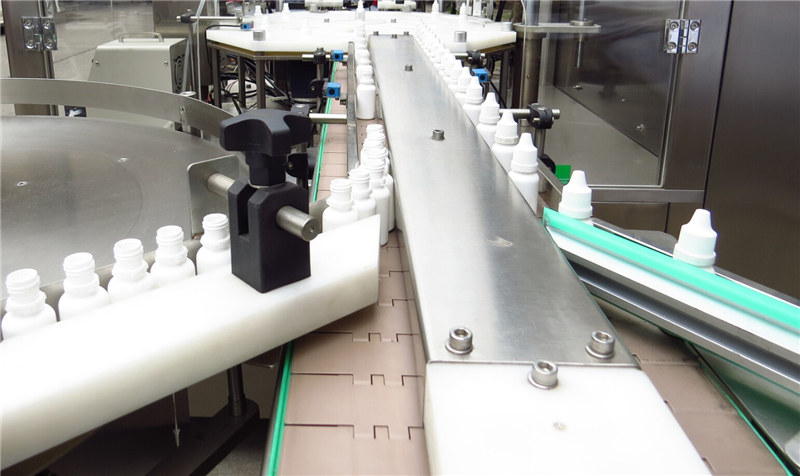

The basic function of to fill the bottle plugging & screw capping , Containers moving on SS Slat conveyor, feed towards the Star wheel which works on the principle of indexing mechanism which rotate clock wise the container entered into star wheel pocket which is the transferred by the star wheel toward filling station where diving type filling nozzle is mounted where the bottle is to be filled The filled container rotate and carry the bottle towards nozzle placing station where oriented nozzle is come in chute by vibratory feeder which pick by vacuum pickup system is spick and rotate 180 and place on bottle after this operation is to be transfer by star wheel to next station where oriented cap is to be come in chute which pickup by vacuum type pick up system is to be picked up by head and place on bottle after this operation is to be transfer for screw capping system where is to be cap is tighten by screw capping as desired torque once it finished the bottle is to be transferred toward exit conveyor for next operation

The housing and surface are covered with stainless steel. All liquid contacts are made from a corrosion resistant stainless steel 316 . Preventing particles be created adopt ceramic filling piston and cylinder. Liquid filling volume to be adjusted flexibly and precisely. The liquid filler has adopted two processing stages available for a gradual upward movement from the bottom of the bottle, to prevent spills and the forming of foam. It is available for filling nitrogen.

The capping system include cap vibrating feeding and capping with torque limiter that ensure caps are tightened.

The electronic devices of this machine are controlled by an intelligent PLC, ensuring that no bottles are feeder, not liquid is filled , no liquid is filled , not plugs are inserted, no plugs are inserted, not caps are capped . It helps the whole production procedure remain smooth with control over quality.