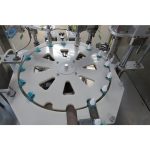

This sprayer pump, glass dropper bottle filling and capping machine includes the turn table feeding bottle, automatic filling, automatic feeding sprayer pumps(glass dropper), capping, labelling and bottle collection table.

Automatic 5-30ml dropper bottle filing capping machine is widely used in filling of various of small bottle in 10-30ml 30ml-50ml 50ml-130ml for e-liquid essential oil massage oil eye drops liquid etc.

The automatic glass dropper bottle filling capping machine is mainly designed for small plastic or glass round and flat bottles and suitable for filling liquid like e-liquid, eye drops, electronic cigarette, nail polish, eye shadow, essential oil and so on. The dropper bottle filling machine adopts the peristaltic pump or piston pump metering with the filling range 10-120ml, high precision.

PLC controller and color touch screen are applied and made it possible for programmable control of the machine. It can finish unscrambling bottle, filling, glass dropper load, screwing the cap, labeling(optional) automatically. No bottle no filling and no capping.

High position accuracy, stable driving, precise dosage, and simple operation and also protects bottle caps.

Brief Introduction:

This sprayer pump, glass dropper bottle filling and capping machine includes the turn table feeding bottle, automatic filling, automatic feeding sprayer pumps(glass dropper), capping, labelling and bottle collection table.

This production consists of bottle feeding table, peristaltic pump filling, feeding sprayer pump(glass dropper), pre-capping, servo capping, labelling and bottle collection table.

Features:

The singe (double) head automatic ointment filling machine adopts programmable logic controller (PLC) human and machine interface technology, equipped with imported photoelectric track switch from Korea, which is suitable for filling ointment products in the industries such as ointment, oil products, syrup, shampoo, bechamel and fruit juice etc. The filling nozzle will be automatically inserted into the bottle to carry out the filling and then rapidly ascend, which can reduce the air bubbles. The product integrates electric and pneumatic functions into one, with reasonable design, stable performance, accurate quantity, glass table surface, automatic bottle feeding, steady operation without noise, electric speed control to the filling speed and filling volume and convenient maintenance and cleaning. The new type filling equipment is the best choice for the realization of automatic production.

Main Parameter:

| Filling volume | Ml | 5-100 |

| Production capacity | Bottle/h | 1500-3000 |

| Quantitative error | % | ≤±1% |

| Cap feeding rate | % | ≥99% |

| Capping rate | % | ≥99% |

| Source voltage | V | Three-phase four-wire system AC220V 380V ±10% |

| Consumed power | KW | 2 |

| Gas supply pressure | MPA | 0.4-0.6 |

| Air consumption | M3/min | 0.2 |

Working Process

- Bottle unscrambling (optional device)

- Peristaltic pump or piston filling (no bottle no filling)

- Glass dropper loaded by vibrating plate (no bottle no loading)

- Cap capping auto

- Automatic labeling machine (optional device)

- Finish bottles collect turntable (optional device)

- Can be connected to the cartoning machine or shrink film machine (optional device)