Brief Introduction

1. This machine can finish a series of operations such as bottle-feeding cap-feeding ,cap-unscrambling and bottle-out .

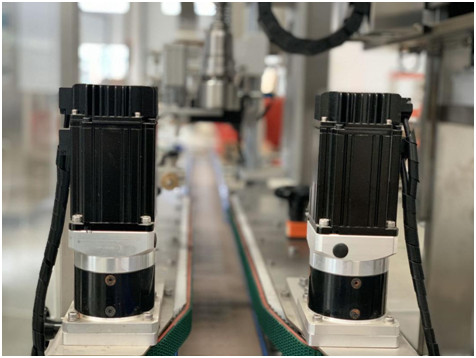

2. We adopt international advanced modular design concept ,including molds cap-sending , cap-grasping by positioning servo-controlled torque .

3. Non-injury of bottle and caps , high efficiency . No caps , no operating . At the same time , this machine can remove the damaged bottles and non-foiling bottles .

4. It uses advance control technology,touch screen , programmable controllers , servo motor combination , product upgrade quickly . About conditioning , just input the arming angle in the touch screen . Then through the screw lifting mechanism to lift the whole place to complete the specifications .

5. It greatly improves production efficiency and friendlier human-machine combination

6. Surfaces were polished, beautiful; This machine step-less adjustable conducive equipped production lines, is the ideal choice for large, medium and small packing plant.

Technological Parameters

1. The main dimensions (length × width × height): 2000mm × 1400mm × 2500mm

2. Weight: 600kg

3. Suitable container Specifications: Height: 50mm ~ 450mm; diameter: ¢ 30mm ~ ¢ 500mm; various parties bottles and bottles without rules

4. Lid height: 10mm ~ 50mm; diameter: ¢ 20mm ~ ¢ 80mm

5. Power:AC 220V/50HZ

6. Total Power:3KW

7. Need to prepare the gas source: 0.6MPa clean air

8. Capacity:20~40P/M

Main Configuration

| 1 | Touch Screen | Delta | Taiwan |

| 2 | PLC | Delta | Taiwan |

| 3 | Frequency Converter | Delta | Taiwan |

| 4 | Arm Control System | Delta | Taiwan |

| 5 | Cylinder | AIRTAC | Taiwan |

Spare Parts List

| NO. | Item | Quantity |

| 1 | Solenoid valve | 1 Piece |

| 2 | Spring | 1 Piece |

| 3 | Tools kit | 1 Set |

| 4 | Tools Box | 1 Piece |

| 5 | Instruction | 1 Piece |

This machine is specially designed for 1-5L lubricant products. It adopts CNC single-track electric single-head grab-type tracking screw cap.

France Schneider servo system, France Schneider PLC programmable control, touch screen man-machine interface operation, all parameters are evenly modified in the touch screen.

Automatic gripping and capping are completed by the servo motor, and the movement is precise and the speed is fast. The servo system + torque module controls the capping head, and the cap tightness is freely set.

When the capping head is working, the set torque is automatically stopped. Electric rotary type capping machine adopts double photoelectric screening for positive and negative cover, and the screening pass rate is 100%.